To deliver zero-defect product, Inrad Optics operates under a comprehensive quality system that includes:

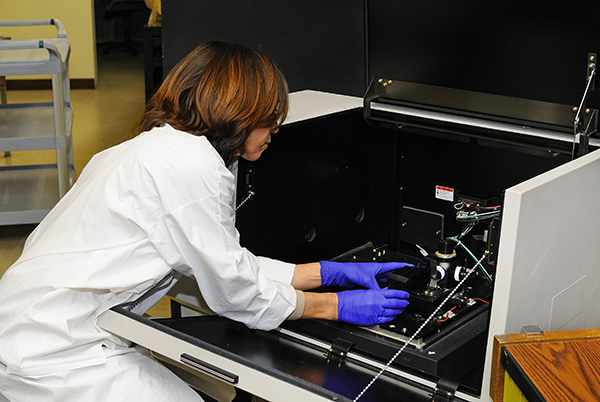

State-of-the-art Metrology. We employ a wide variety of metrology techniques to ensure that all optical properties and dimensions are within specification.

Strict Adherence to Technical Requirements. All customer specifications are carefully analyzed and clarified prior to commencement of production. Most of our production additionally complies with latest-revision DOD and ASTM specifications.

Tracking and Traceability. Our MRP system allows us to electronically track and document every product on its journey through the manufacturing life cycle–from initial order and design review to manufacturing, quality assurance and shipping. The system offers shop-floor access to detailed customer specifications along with relevant DOD and ASTM requirements.

| Metrology Capabilities | ||

|---|---|---|

| Metrology Instruments | Parameter(s) | Measurement Sensitivity |

| Zygo Digital Interferometers up to 18" | Surface Figure | 0.005 waves |

| TWE & RWE | ||

| Parallelism | 1 arcsec | |

| Wyko & Chapman Optical Surface Profilers | Surface Roughness | 1 Å |

| Hitachi and Perkin Elmer Spectrophotometers & FTIR | Spectral Characteristics | ± 0.05 %T |

| ± 0.01 %R | ||

| Zeiss CMM | Mechanical Dimensions | 1 µm |

| Trioptics Prism Master | Angular Accuracy | 2 arcsec |

| Nikon Autocollimators | 0.5 arcsec | |

| Angle Gauges & Indexers | 0.1 arcsec | |

| X-ray Diffractometer | Crystalline Orientation | Rough: ± 5 arcmin |

| Fine: ± 1 arcsec | ||

| High Intensity Fiber Light | Surface Quality (S-D) | per MIL-PRF-13830 & ISO 10110 |

| Tenney Micro-Temm II, BMA | Environmental Durability | Temperature, Humidity, Salt Fog per MIL-C-48497, MIL-C-675, MIL-F-48416 |